So the stars aligned to offer me the chance of a lifetime to design, curate and build a museum dedicated to Britain’s industrial past from scratch.

A part time job as the caretaker at Botley Mills evolved into a full focus on bringing their Heritage Centre to fruition – a project that has tapped into a broad spectrum of my interests, skills and knowledge as well as helping expand them considerably too.

The opportunity emerged when I helped my employer pull together material and displays for their Centenary celebrations at the end of 2021. At the evening event it was announced that a space dedicated to the history of Botley Mills would be created during the following year.

As soon as I saw the part of the old mill building that was being designated as a museum space my mind went into overdrive imagining the story that could be told in exhibits and graphics.

Once Ken, the mill’s resident builder, had done an absolutely sterling job fixing beams, floors, walls and ceilings, as well as adding toilet and kitchen facilities I had an excellent blank canvas to work with.

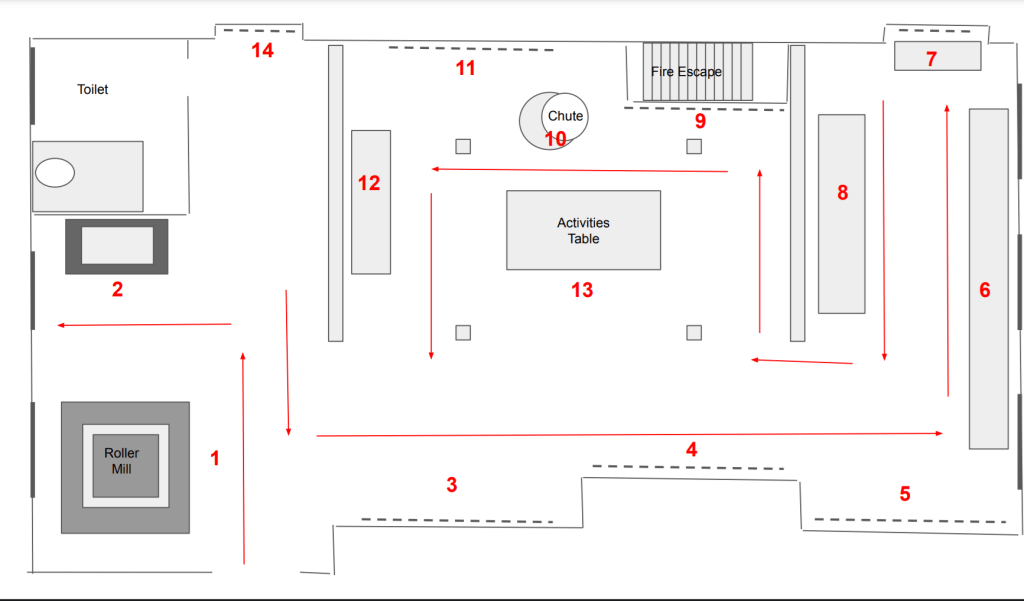

After walking around the space and studying the previous work that had been done back in the 1990s to envisage a working roller mill museum in another part of the enormous site, I came up with a proposal for topics and visitor flow that covered off all the key aspects of milling from the 1000 plus years of history at this location.

Once this was agreed in principle by the mill owners, the Appleby family, I took a much deeper dive into both the history of the Botley site and milling in general.

Socio-economic history was one of my favourite subjects at school and college and if I had put in enough effort to get to university it would have been what I studied at degree level. Therefore it was a pleasure to get down in the detail and develop as compelling a story as possible through the exhibits and graphics.

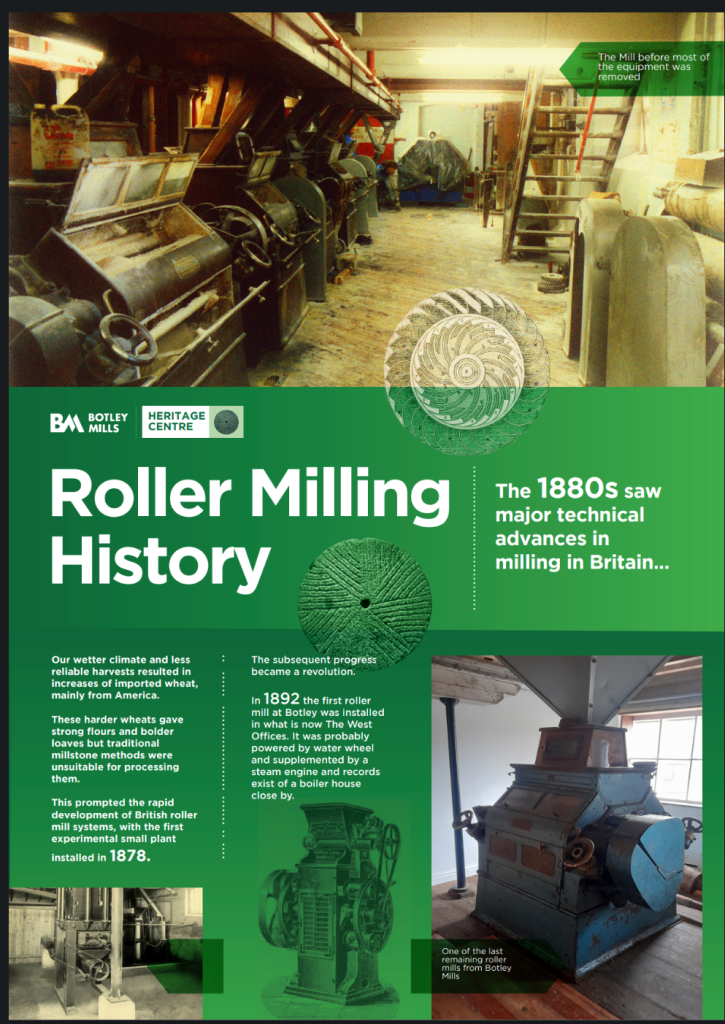

As the space by the entrance door had a roller mill machine that had formed part of the production processes at one time it made sense to make the first part of the story about the science and engineering of roller milling and how it differs from traditional stone ground milling.

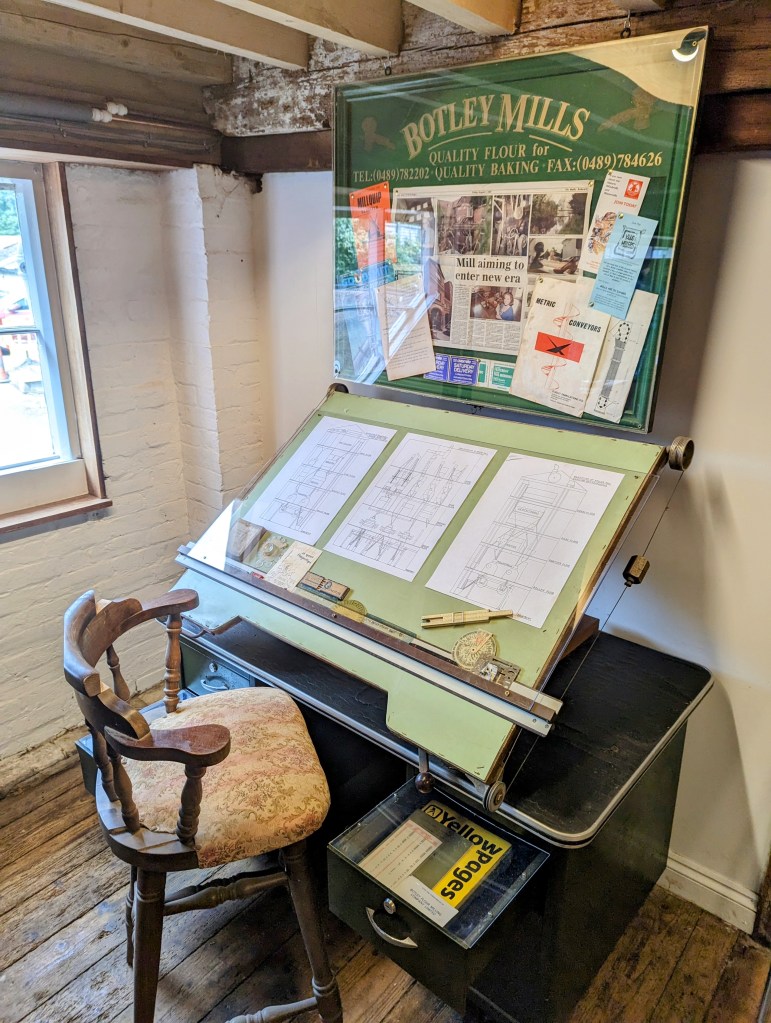

At a later point, part of the space had been used as a drawing office and contained a lovely Art Deco style metal desk with a drawing board on top.

I had an immediate affinity with the drawing board as it is a smaller version of the one my father had for decades in his home studio.

The drawing instruments and office items, including a pristine copy of the Yellow Pages still in its polythene wrapper, were a time capsule of workplaces in the 1970s and 80s that deserved to be displayed as a testament to how things have changed with the advent of computerisation, the internet and digital communications.

Also this was the location where the working roller mill museum plans were conceived and developed by one time Technical Director, Patrick Appleby, and so it seemed appropriate to display those drawings. As the museum was going to be a smaller scale illustration of what existed originally in other parts of the site it was also a good way of showing all the elements involved in turning raw wheat into finished flour products and how material travels up, down and across the facility through elevators, conveyors, pipes and chutes.

There were pieces of equipment relevant to the roller milling processes that I wanted to put in this area but, as with anything to do with old engineering is concerned, it is all extremely heavy and can be a logistical challenge to move it from one part of the mill to another.

In some instances I had to construct a scaffold framework and use chain hoists to move items through different levels. It could take a whole day just to get some exhibits in place.

Also, the scope of the project tended to drift as I spotted new opportunities to tell the mill’s story.

From the moment I started working at the mill I was fascinated by a piece of equipment known as a wheat dampener. It had this intriguing red unit on top of a large white cylinder.

Once the spaces started to come together as per my original floor plan I could see where other items could be added to expand and enhance the story.

Alongside the graphics that explain the roller milling process and equipment from beginning to end was a bit of a dead space around one of the big beams.

The more I looked at it the more it looked ideal for placing the top part of the wheat dampener machine and also presented an opportunity to motorise it and illustrate how the little buckets were used to control the water volume .

I managed to separate the red unit from the white cylinder relatively easily but it was very heavy and awkward to move. Another day of logistics got it into place and with further time the temporary shelf I made within the beams was replaced with a purpose built stand. Although it is just static right now I hope in a further phase of development it will be brought back to life and become an interesting feature and talking point that draws people into the Centre encourages them to learn more.

Added to the logistics of moving the exhibits around the site the other big challenge was getting the floor to look more attractive without losing the charm and story of a one time busy working environment.

The oldest part of the mill is believed to date back to the mid 1600s. Therefore parts of the floor are likely to be over 300 years old. Wet rot, dry rot, woodworm and wear and tear have taken their toll on these oldest parts of the structure and different approaches to repairing it over the years have resulted in a patchwork of different surfaces. Other parts have been protected from the elements because of a thick layer of oil, flour and dirt that had been compacted on top.

Because of the wildly undulating nature of the old floor areas in particular as well as protruding nail heads and use of different patching materials like leather, tin and canvas, an attempt to use a heavy duty floor sander proved largely unsuccessful so in the end I spent the best part of two weeks on my hands and knees stripping the surfaces back to a uniform state using a wire brush attachment on a power drill. I’ve never been so filthy from head to toe over so many days in my life before but the eventual result made it worthwhile.

In the majority of the areas I managed to blend the newer flooring with the older and original areas.

One part of the space where this was not so straightforward was down by the front windows. This has traditionally been a very high traffic area within the old working mill and the section where sack trucks would have trundled day in day out is covered in lengths of heavy duty canvas belt that at one point would have been used to power the machines. It is a very tangible example of how the fabric of a building can bring old stories back to life for later generations.

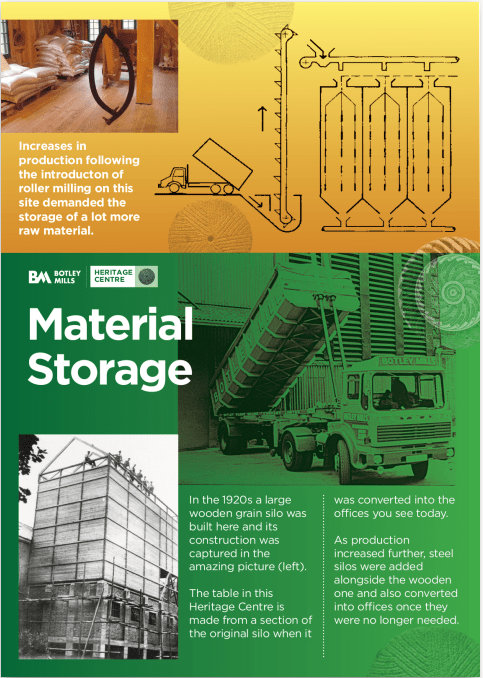

Another way we incorporated the old fabric of the building was using a section of the 100 year old wooden silo structure as an amazing top for something now described as the ‘activities table’. The underside of the table is a large wooden trough on wheels that was used for moving materials around in this part of the old mill.

Take a look at the official web page for the new Heritage Centre here …

https://www.botleymills.co.uk/heritage_centre

Better still, if you are ever in or around the lovely Botley village pop in for a look – It’s all free 🙂

Also – an old site I built to help the current mill owners celebrate their Centenary a couple of years back is still visible here … https://botleymillsheritage.co.uk/ (It needs tidying up after a Drupal 10 upgrade but still has loads of great pics not visible elsewhere)